12. Product System Services

Version 0.4

Latest edition: Jean-Luc Garnier, December 14, 2017, 12:00.

This chapter is the result of a collaborative work of experts who are members of the Technical Committee “Systems of Systems, Services - Architecture and Engineering” (CT 3SAI) of French Chapter of INCOSE (AFIS). This chapter is dedicated to Product-Service Systems (PSS) and is intended to be the 12th chapter of a “Service Systems Engineering – Body of Knowledge”.

This chapter starts with PSS Engineering key figures in a Systems Engineering perspective. The second part provides key concepts with definitions, ontology and lifecycle considerations. The third part addresses economic considerations including typology, functional economy approach, offering and business model. The last part is dedicated to modeling and simulation.

Key-words: PSS, product, system, coupling, servitization, service, ontology, lifecycle, functional economy, offering, modeling, simulation

Service Systems Engineering Body of Knowledge Chapter 12 – PSS - Authors

- Thècle Alix – Université de Bordeaux

- Xavier BOUCHER – Ecole des Mines de Saint Etienne (EMSE)

- Khaled Medini – Ecole des Mines de Saint Etienne (EMSE)

- Claude Pourcel – École d'Ingénieurs en Génie des Systèmes Industriels (EIGSI)

- Emmanuel Caillaud – Université de Strasbourg

- Yann Chazal - Renault

- Anne Sigogne – Retired

- Pierre-Olivier Robic - Thales

- Eric Gauthier - Thales

- Jean-Luc Garnier - Thales

Service Systems Engineering Body of Knowledge Chapter 12 - PSS Project Manager:

- Xavier Boucher – Ecole des Mines de Saint Etienne (EMSE)

- Pierre-Olivier Robic - Thales

Service Systems Engineering Body of Knowledge Project Manager:

- Pierre-Olivier Robic - Thales

AFIS CT 3SAI: Leaders

- André Ayoun – Airbus Defense & Space

- Claude Pourcel – École d'Ingénieurs en Génie des Systèmes Industriels (EIGSI)

.

Contents

- 1 Introduction on the field of PSS Engineering

- 2 References and Definitions on Key Concepts of the PSS domain

- 3 Specificities of the economic model

- 4 Contribution to a state of the art on modelling, simulation, and engineering of Product-Service Systems

- 5 REFERENCES

Introduction on the field of PSS Engineering

Introduction

During the last decade, the manufacturing industry has undergone a paradigm shift through the development and spread of servitization and Product Service System (PSS) concepts. From the point of view of industrial managers, the transition towards Product-Service-Systems has to be managed as a change of business model, where PSS are implemented as an innovation strategy, shifting from developing and selling physical products to developing and selling the use of a system of products and services capable to adapt easily to personalized demands of clients (acquirers and end users). Coupling, or even integrating, industrial production and service delivering poses many innovative challenges for the manufacturing industry at the technological, organizational and even human levels.

To support this complex transition towards the business integration of services and products, the methodologies and tools supporting the design and the engineering of systems and offers have to be quite drastically adapted. Product-oriented Design Methodologies or System Engineering Methods and tools are deeply affected by the necessity to integrate new concepts linked to usage capture and analysis, design of services and their life-cycles, interactions between product and service life cycles. Prior to a survey of PSS design and engineering tools and methods (see ?4), this first section introduces progressively the concept of Product-Service-System by positioning first key definitions linked either to product or to service.

Product: technological & service ones

Product general definition

A Product is intended to be sold, directly or indirectly (case of an internal product) to customers for satisfying their expectations (integrating end users employment) and meeting their operational requirements. A Product can be hardware or software equipment or a service or a system or a mix.

From an engineering definition, a (work) product is the result of an activity.

Service basic concepts

Many definition of the term exist having in common the three following elements: the service provider, the service client and the service target (Spohrer, 2007).

The three main characteristics of service are:

- The co-creation of value: idea of the customer as co-producer of the value extracted from the service sys-tem and input to the service process

- Relationships: the relationship with the customer is of paramount importance and is a source of innovation and differentiation. Long-term relationships facilitate the ability to tailor the service offerings to the effective customers’ needs

- Service provisioning: there is a provision service capability to meet fluctuations in demands while retaining quality of service

Note: in this chapter, we refer to “Engineering” in an INCOSE understanding. Engineering includes Design activities.

According to (Balin and Giard, 2009) “that it's almost impossible to provide a short definition of "service" which is valid for the whole service sector.” but that “it's possible to gather some common aspects of services in one definition with a specific approach.”

Then, "A service can consist in:

- Products provision to the customers by means of operators or of machine,

- Providing simple or complex information to the customer following his request, where the material support of this information is not essential,

- The modification of the state of certain resources (equipment, person...).”

Or else, it can concern:

- An action: transitory, intangible and that don’t require the possession of the production factors (Berry, 1980).

- A set of activities: interactions between customers and contact people to respond to customer’s needs (Gronroos, 2000.

- An economical activity: creation of value to respond to customers’ needs and to provide consumers with advantages (Vogler, 2004).

- A result: free or charged advantage proposed to an individual, a company or a public or private organizations

Most of the time it contrasts with goods because of the four dimensions that can be associated: (i) immateriality, (ii) a contact between a contractor and a customer for service production, (iii) a participation of the customer in the production process and (iv) a definition of objectives stemming from a compromise between the interacting persons render the output of the service production process quite “fuzzy” (Gallouj, 1997), (Eiglier, 2000).

To summarize “Service” characteristics are [Lovelock, 2004]

- A service is not owned, but there is a restricted access.

- Services have intangible results.

- Customers are involved in the service production process.

- Other persons than the customer can be involved in the service process.

- Quality in service is difficult to control while increasing productivity.

- Quality in service is difficult to apprehend.

- Service cannot be stored.

- Service delivery delay is crucial.

- Service delivery integrates physical and electronic way.

The characteristic of intangibility abovementioned associated to the one of heterogeneity, inseparability and perishability usually used to differentiate a product from a service have lost value and should be avoided in the case where attention is paid on service value creation because they do not capture the process and interactive nature of services (Edvardsson, 2005).

Coupling technological & services products (product to equipment and managed services) in a perspective of service provisioning

Fully based on the work developed in the European project MSEE, this section presents the concepts based on the initial work in (Thoben et al. 2001) which make possible articulating clearly the notions of products and services, which leads then to the concept of Product Service Systems further specified in section 12.2. To introduce product-service coupling, these concepts start from an initial core product.

Extended Products

The concept of extended products delivers an appropriate model to link products, product related services and the needs of the users.

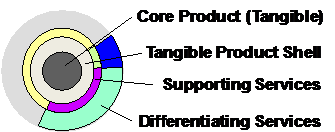

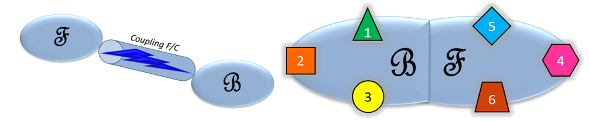

Figure 1 - The Extended Product Concept (MSEE project)

The Core Product is the physical product that is offered on the market; while the Product Shell describes the tangible “packaging” of the product). Supporting Services are intangible additions, which facilitate the use of the product (e.g. maintenance plans or mobility guarantees). Differentiating Services provide individualization of the Extended Product on the market.

In a Product Line perspective, the product considered is analysed in order to define a standard core and to define the relevant options, in order to provide a variability to support the strategy. This variability should enable to provide an instantiation that fit with a changing target market.

By analogy, a product of service should be defined thru a core service (building block approach) with options.

Consequently, in a PSS and product line perspective, driven by the strategy, the objective will be to define the relevant package based on the relevant core service and core product plus the relevant and compliant options (for both service and technological product). These packages can evolve through lifecycle.

One of the major associated challenges is to provide a relevant configuration management enabling to ensure the integrity of the solution through lifecycle, challenge quite similar to configuration management in a system of system context.

From {Product+Service} to Product2Service

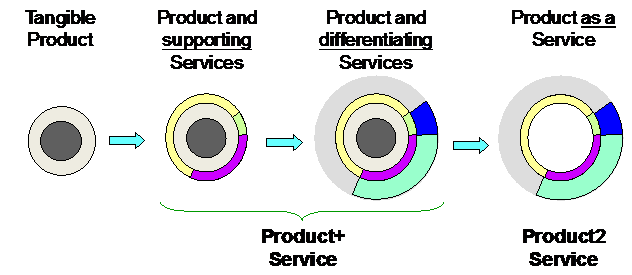

Customers are looking for solutions and benefits (not for products) or even more they are requesting intangibles like fun, success, fame, vanity etc. Manufacturers need to package their core products with additional services to make them more attractive. This process of servitization is shown in the figure bellow, which shows the development from the tangible product to {Product+Service} then Product2Service scenarios

Figure 2 - Scenarios for progressive integration of service (MSEE project)

{Product+Service} scenarios describe the simultaneous offering of the tangible product (Core Product and Shell) extended with proper tailored services. In this case, both physical products and services contribute to the revenues, their balance needs to be adaptively determined and continuous innovation of services assumes a key competitive advantage. Product2Service scenarios are in contrast sharply decoupling manufacturing of goods and selling of services, where in most cases physical goods remain the property of the manufacturer and are considered as investment, while revenues come uniquely from the services.

Service Systems in the context of the Information Technology

The service industry considers service system under the following definition: a configuration of technology and organizational networks designed to deliver services that satisfy the needs, wants or aspirations of customers. Service system includes: service provider, service customer, service environment and technical support. In the IT industry, software as a service is a widespread PSS (Bohmann, 2008).

The computer science has proposed a service-oriented architecture that rests on the combination of a process innovation with an effective-governance, a technological strategy centred on the definition and on the re-use of services. Here, functionality is decomposed in a set of functions or of services supplied by components. A business service is a company functionality that seems to be atomic from the service consumer point of view.

- A service system is an integrated and interdependent combination of component resources that satisfies service requirements. A service system encompasses everything required for service delivery, including work products, processes, facilities, tools, consumables, and human resources. Note that a service system includes the people necessary to perform the service system’s processes. (Glossary of CMMI, 2010)

- A service system is a work system that produces services. A work system is a system in which human participants and/or machines perform work using information, technology, and other resources to produce products/services for internal and external customers. All work systems involved in economic exchange are services systems because they perform work to produce something for the benefit of others. A very small percentage of work systems are not service systems because they involve someone performing work only for personal benefit (Alter, 2011).

From traditional pure manufacturing approach to an IPSS approach

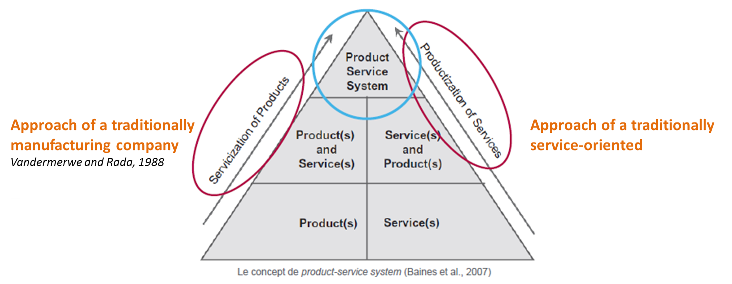

Figure 3 - Matthieu YAGER - GSCO

National differentiation-inducing factors or international competitiveness-inducing factors, the addition even the replacement of product being sold as services are for industrial companies a new source of turnover and a customer loyalty lever. Doubtless, at the present time, income generated by sales of services and PSS sales is higher than those generated by product selling. Nevertheless, the evolution towards new activities implies managerial and organizational developments that are out of reach for most SMEs or even some large industrial companies. Four dimensions need to be taken into account (Alix, 2010):

- The product,

- The service,

- The processes,

- The system

Having a customer and user centric view and taking care to the environmental impact.

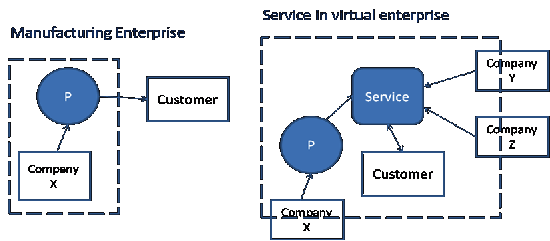

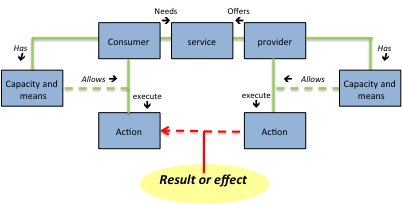

Compared with traditional single enterprise producing products, service in virtual enterprise is an (temporal) association of several enterprises to provide one or several services around a product. The main feature of service in a virtual enterprise can be illustrated by the figure below.

Figure 4 - Manufacturing enterprise vs. service in virtual enterprise

The main characteristics of service in virtual enterprise are: (1) customer is part of the enterprise, (2) it involves several companies, and (3) only part of each company participates in this virtual enterprise.

PSS as a result of systemic approach

Historically, the scope of engineering was focused on the development of a technological system according to a set of requirements part of a specification of needs or similar. The scope of performance was mostly intrinsic ones.

Service was mostly related to support to equipment service and service engineering was performed thru ILS approach. The scope of performance was mostly capabilities ones.

More and more, the objective is to get an effective operational performance. Consequently, the needs are formalized thru OCD (including CONOPS, CONEMP & CONUSE) and the IVVQCA activities are performed against this. To engineer a proper solution, PSS based, not only the technological product & the support to equipment are considered but also the system of operation, as part of the whole environment.

This transformation is mostly due to the search of effective results, in a real environment, including all the bias compare to models. This approach enable to prevent from bias in the transformation of the needs expressed into requirements.

The system of support and the system of operation are both socio technical system. This means that not only technological component need to be considered but also the organization and its procedures, the operational procedures and the stakeholders dramatically () human.

Consequently, the scope of consideration migrates from technological concerns to socio technological ones, especially including human factors and process & procedures.

This should be taken into account in the perspective of servitization, especially to drive the type of skills & competencies to take onboard to engineer a solution.

Impact regarding product definition: toward an extended PBS

This chapter will be developed in further edition of this document. The aim of this part is to describe the key elements of PBS subject to verification with regards to needs.

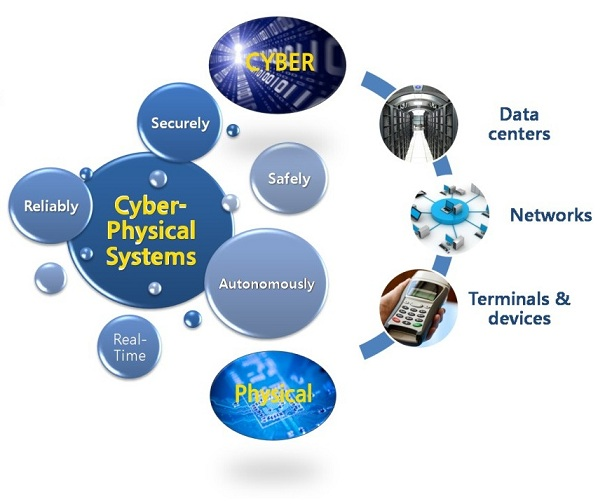

A transition to services based on Cyber Physical Systems

With Digital Transformation, there is a global trend for smarter, more interconnected and interdependent, collaborative and autonomous solutions. On a system point of view, this is a transition to Cyber-Physical Systems. Best opportunities for these Cyber-Physical Systems are often pointed on the development of complex services in new “smart” domains as Cities, Health, Energy, Mobility, Manufacturing…

“The term Cyber-Physical System (CPS) describes hardware-software systems which tightly couple the physical world and the virtual world, under the control of humans. They are established from networked embedded systems that are connected with the outside world through sensors and actuators, acquiring data streams from the physical world, establishing and continuously updating a virtual twin of the physical world and with the capability of interacting with the physical world, following instructions from the virtual sphere. Furthermore, CPSs are not merely networked embedded systems but software-intensive, intelligent systems with the capability to collaborate, adapt, and evolve. CPS can be considered to be the technological foundation for the Internet of Things in which every physical object has a virtual representation and in which the physical and virtual reality form a continuum.” (EU H2020 project Road2CPS)

Figure 5 - Cyber-Physical System properties

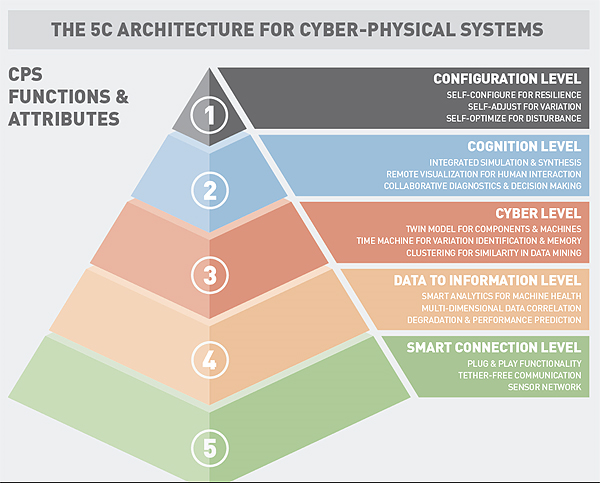

Figure 6 – The 5C Architecture for - Cyber-Physical Systems

http://www.designworldonline.com/big-future-for-cyber-physical-manufacturing-systems/

Even if digital transformation tends to make these CPS believable in a short term, there are still some major issues to address:

- Interoperability

- Modelling and simulation performance since CPS are designed, continuously improved and modified, first in the virtual world

- Safety, security and privacy because standards, certification process and regulations are not adapted yet to this kind of systems

- Big data, because with so many devices and sensors, huge amounts of data are generated which is both a challenge and an opportunity if velocity, volume, variety and veracity can be achieved

- Integration with humans, so that humans would be willing to trust and accept these systems

We can notice here that these key issues are not only technological locks. Interactions with social, legal and business concerns are again crucial, and will require a large research effort from the community.

References and Definitions on Key Concepts of the PSS domain

The concept of PSS: definitions and typologies

Product Service Systems present the advantage of representing an interdisciplinary field, which attracts many distinct points of view and contributions. Until now, the concepts, definitions and typologies concerning PSS mainly come from scientific works: the notion of PSS challenges researchers from many distinct research areas:

- Typically, business management mostly investigates bundling of products and services from a marketing perspective. A well-recognized definition in this area considers PSS as “a market proposition that extends the traditional functionality of a product by incorporating additional services” (Baines 2007).

- However, the orientation on sustainable development has been a key focus for the deployment of this type of business model, leading Mont (2002) to define PSS as : “A system of products, services, supporting networks and infrastructure that is designed to be: competitive, satisfy customer needs and have a lower environmental impact than traditional business models.”

- More recently a growing interest has converged on the transformation on industrial business models. Putting forth the industrial dimension, Meier (2012) considers that “an Industrial Product-Service System is characterized by the integrated and mutually determined planning, development, provision and use of product and service shares including its immanent software components in Business-to-Business applications and represents a knowledge-intensive socio-technical system”

These 3 examples are not exhaustive at all and just underline some of the key perspectives of PSS development. As intent of synthesis, we can underline the following characteristics of PSS business models:

- PSS are defined as « value proposition » (Chesbrough, 2002), (Vandermerwe et Rada, 1988) where the transactional unit is no more the product by itself but the function delivered by the product.

- A global offer of product and services, designed and coordinated all along the process of value creation, and integrated by the internal organisation of the PSS. A PSS can be fully considered as a System of System.

- From the industrial manufacturer point of view, PSs are characterised by a transformation de ‘focus’ of the production processes: new ‘object of production’ based on the integration of product and services over the whole life cycle (Design, Production, End of Life, Evolution of the offer,…).

- As a consequence of their complex integration of subsystems, PSS are characterised by dynamics of networked co-production (customer/user contribution, collaborative production networks, and multiple stakeholders), generating new forms of value creation process & value creation factors.

- The product service-system intents to increase the value of the product in use, to better satisfy the usage needs and comes within a perspective of minimisation of the environmental impact..

The following Table provides a rather broad view on different kinds of definitions for PSS, with their specificities.

Table 1 - PSS definitions

| Concept of system | Marketing | Tangibility, intangibility | Netwokrs, infrastructures | Sustainability | Social Aspects and parnterships | Industrial process | ||

|---|---|---|---|---|---|---|---|---|

| Goedkoop· et al., 1999 | A marketable set of products and services capable of jointly fulfilling a user's need. The PS system is provided either by a single company or by an alliance of companies. It can enclose products (or just one) plus additional services. It can enclose a service plus an additional product. And product and service can be equally important for the function fulfilment. | * | * | |||||

|

Manzini et al., 2001 |

A business innovation strategy offering a marketable mix of Products and services jointly capable of fulfilling client needs And/or wants with higher added value and a smaller environmental impact as compared to an existing system or product. |

* | * | |||||

| Mont, 2002 |

A system of products, services, supporting networks and Infrastructure that is designed to be: competitive, satisfy customer needs and have a lower environmental impact than traditional business models. |

* | * | * | * | |||

|

Manzini, Vezzoli, 2003 |

A product service system (PSS) can be defined as "an innovation strategy, shifting the business focus from designing (and selling) physical products only, to designing (and selling) a system of products and services which are jointly capable of fulfilling specific client demands”. | * | * | |||||

| Tukker, 2004 | A system consisting of tangible products and intangible services designed and combined so that they Jointly are capable of fulfilling specific customer needs. | * | * | * | ||||

|

Halme et al., 2006 |

Products and services which can simultaneously fulfill people's needs and considerably reduce the use of materials and energy | * | * | |||||

|

Krucken., Meroni, 2006 |

An advanced industrialised solution based on collaboration between social players, which gives rise to both effective and efficient, highly contextualised services | * | * | |||||

| Morelli, 2006 | A social construction, based on "attraction forces" (such as goals, expected results and problem-solving criteria) which catalyse the participation of several partners. A PSS is a result of a value coproduction process within such a partnership. Its effectiveness IS based on a shared vision of possible and desirable scenarios. | * | * | |||||

|

Baines et al., 2007 |

A market proposition that extends the traditional functionality of a product by incorporating additional services. | * | ||||||

| Meier et al., 2010 | An Industrial Product-Service System is characterized by the integrated and mutually determined planning, development, provision and use of product and service shares including its immanent software components in Business-to-Business applications and represents a knowledge-intensive socio-technical system | * | * | * | ||||

|

Boehm, Thomas, 2013 |

A Product-Service System (PSS) is an integrated bundle of products and service which aims at creating customer utility and generating value | * | * | |||||

| Furrer, 1997 |

A product-service is a service supplied in addition to a product increasing its value for the customers Note: Considering labor forces distribution, added value and gross domestic product sharing out in developing and developed countries, the service economy is growing even in the manufacturing area. Services constitute a source of innovation whatever the sector of activities. Manufacturers propose services around the product they deliver. |

|||||||

| Brandsotter 2003 | PSS consists of tangible products and intangible services, designed and combined so that they are jointly fulfilling specific customer needs. Additionally PSS tries to reach the goals of sustainable development. | |||||||

| SUSPRONET (http://www.suspronet.org/) | Product-service is defined as a value proposition that consists of a mix of tangible products and intangible service designed and combined so that they are jointly capable of fulfilling integrated, final customer needs and a product-service system (PSS) as the product-service including the network and infrastructure needed to ‘produce’ a product-service. |

Main contributions from the PSS academic community concern the principles, strategy, and development in PSS, service design methods and service engineering (Tomiyama, 2001). Concerning these two last points, the main value added is to consider each step of the system life cycle to ensure value delivery. These aspects will be addressed in a dedicated chapter of the Service Systems Engineering Book of Knowledge titled “Service Systems Engineering – activities description”.

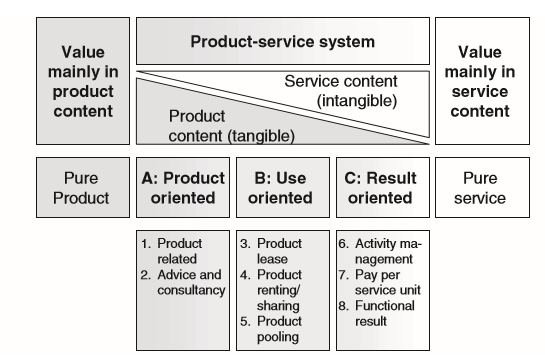

Depending on the way to associate or integrate product and services, but also depending on the type of economic model deployed, distinct kinds of PSS can be considered. A typology of product-service systems has been progressively proposed based on works by (Hockerts 1999), (Brezet et al, 2001), (Zaring et al., 2001), (Behrend et al., 2003), (Tukker, 2004), or more recently (Baines & al., 2007). These authors have progressively converged towards a widely accepted typology :

- Product Oriented PSS: the product is sent in an ordinary fashion, but the sales contract includes services deployed along the product life-cycle.

- Use oriented PSS: the provider only contracts an access or a utilization of a product, without product purchase for the customer.

- Result oriented PSS: Independently of any pre-defined product, the provider guaranties to answer specific customer needs, with a contracted engagement on the final result/performance.

Figure 7 - Usual PSS typology

Consequently, regarding the Industrial Product-Service System (IPS2), ‘‘An IPS2 is characterized by the integrated and mutually determined planning, development, provision and use of product and service shares including its immanent software components in Business-to-Business applications and represents a knowledge-intensive socio-technical system’’. This means in detail (Meir, 2010):

- An IPS2 is an integrated product and service offering that delivers values in industrial applications.

- IPS2 is a new product understanding consisting of integrated product and service shares.

- IPS2 comprises the integrated and mutually determined planning, development, provision and use.

- IPS2 includes the dynamic adoption of changing customer demands and provider abilities.

- The partial substitution of product and service shares over the lifecycle is possible.

- This integrated understanding leads to new, customer-adjusted solutions.

- IPS2 enable innovative function-, availability- or result-oriented business models.

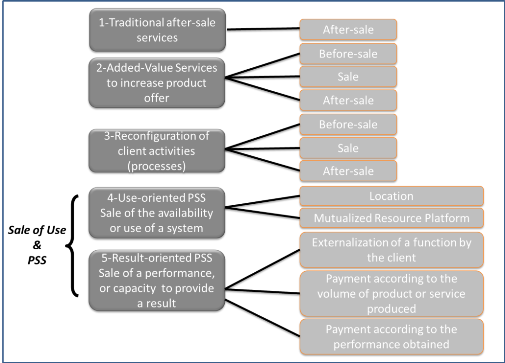

A deeper vision of the same typology has also been used in the context of the ANR ServINNOV project (Boucher & peillon, 2015). Based on academic contributions, the objective is to propose a generic PSS classification, adaptable to any kind of industrial product-service offer, and helping the exhaustiveness and creativity when analysing some new industrial case study. The classification proposed is notably based on the typologies established by (Hockerts 1999), (Tukker, 2004) and (Gebauer 2012). As presented in the figure below, the classification is constituted of two levels, with five service categories on the first level, further refined on the second one. Each category refers to some opportunity to develop services associated to an industrial product.

Figure 8 - PSS Typology (Boucher & Peillon, 2015)

Elements of Ontology and Meta-models

Basic concepts from Service Sciences

In the last decade, a new research stream has merged, trying to systematize the multi-disciplinary knowledge involved in service systems: Service Science Management and Engineering (SSME) was the name given by IBM to this new discipline, in analogy with the Computer Science term coined by IBM in the 70’s (IBM, 2004). However, currently SSME studies and researches have been mostly devoted to support tertiary sector domains (e.g. banking & finance, tourism, trade, public administration), with an obvious focus on ICT.

SSME proposes to build service knowledge and basic theories, to manage and optimize the process of creating value with service and to apply theory to solve practical service problems.

Among the highlighted concepts that we recall are the service dominant logic concept, the service system role-holders concept, the service mindset concept and the service system.

- Service-dominant logic (S-DL): The service-dominant logic world view, upon which service science is based, advocates that service is value co-creation interactions undertaken when service systems create, propose and realize value propositions, which may include things, actions, information and other resources. Value propositions are built on the notion of asset sharing, information sharing, work sharing (actions), risk sharing, as well as other types of sharing and exchange that can co-create value in customer- provider interactions.

- Stakeholders: also known as role-holders in service systems. Role-holders are people, or other service systems, that fill named roles in service systems. The two main roles in any service system are provider and customer.

- Service mindset: a focus on innovating customer-provider value co-creation interactions (service systems and value propositions, SSME qualified) that is combined with the interactional expertise capabilities of an adaptive innovator to enable team work across academic disciplines and business functional silos.

- Service system: is a dynamic value co-creation configuration of resources. Service systems are a type of system of systems; in which value proposition connect internal and external service systems. The smallest service system is a single person and the largest service system is the global economy.

- Service sourcing: agreed commodity definitions, identifying expected outcomes of customer needs and outcomes, determining cost drivers, defining and communicating requirements, defining supplier evaluation criteria.

In this domain, Service Oriented Architectures (SOAs), have de facto revolutionized information systems, by providing software engineers with powerful methodologies and tools for decomposing complex systems into autonomous components, with the final aim to support enterprise vital processes and workflows, by simple orchestrations and compositions in the hand of business specialists. In this field several definitions highlight key features of the service concepts:

- “Service is the application of competence for the benefit of another. So service involves at least two entities, one applying competence and another integrating the applied competences with other resources and determining benefit (value co-creation). We call these interacting entities service systems.” (Spohrer, 2008).

- “A service is present at a time “t” in a location “l” if, at time “t”, an agent is explicitly committed to guarantee the execution of some type of action at location “l”, upon the occurrence of a certain triggering event, in the interest of another agent (although at the cost of a certain sacrifice), in a certain way.” (Ferrario et al., 2008).

- “A service is a transaction where one party grants temporary access to the resources of another party in order to perform a certain function and a related benefit. Resources may be human workforce and skills, technical systems, information, consumables, land and others.” (Orestis et al., 2011).

As a synthesis model, Bullinger et al. (2003) consider 3 dimensions to characterize services: a structure dimension (ability and willingness to deliver the service), a process dimension (a service is performed by the execution of specific processes) and the outcome dimension (The outcome of a service consists in material and immaterial consequences). To structure this conceptual vision, they integrate a product, process and resources model within a basic service-oriented model (figure below)

Figure 9 - Service Model by (Bullinger et al., 2003)

PSS conceptualisation based on ontology

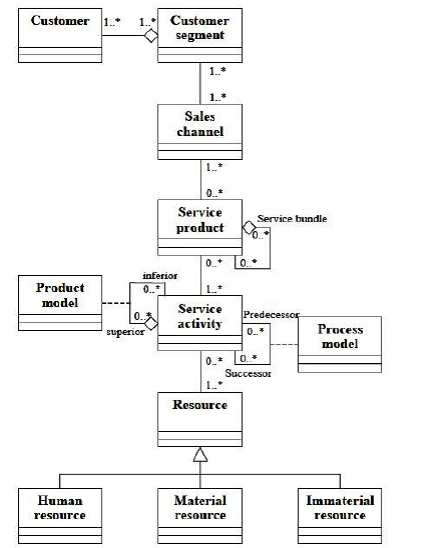

Extending this research of concepts useful to design and manage PSS Systems, Cranfield University has developed a research work intended to provide a quite exhaustive vision and articulation of the concepts related to PSS. The objective of this ontology development was to clarify the key concepts associated to PSS and to share a common vision which could help the collaboration between practitioners and researchers. These developments include the collection of PSS concepts –as illustrated below-, their definition, their grouping and structuring based on the identification of relationships between these concepts. This ontology has been developed from scratch, referring to existing concepts underlined by the academic literature, and based on interviews with experts regarding practices and challenges within the PSS domain.

The resulting ontology is structured around the key concepts underlined by the figure below (Cranfield, 2010):

Figure 10 - Root concept of PSS Ontology

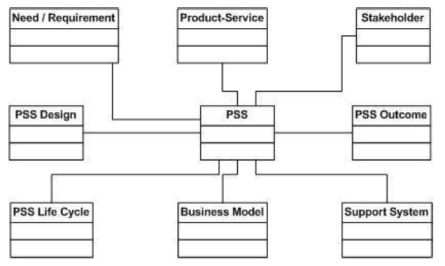

Each of these root concepts has been further associated to a set of related notions, as illustrated by the example below, linked to PSS Life Cycle. PSS Life Cycle is considered as an integration of the life cycles of services and products to a common life cycle.

Figure 11 - Detailed ontology for PSS Life Cycle

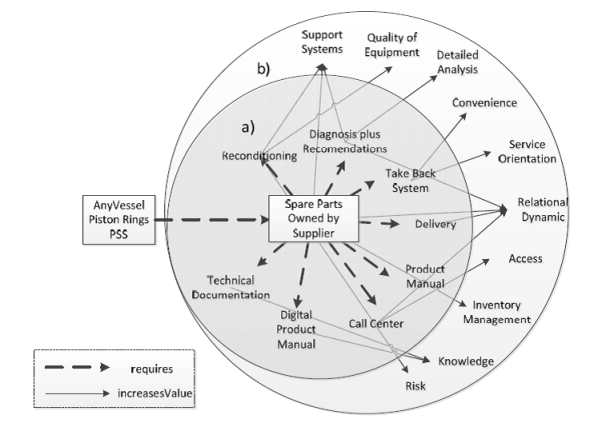

If this first ontological work has been developed to provide a quite exhaustive conceptual view on PSS, additional works have intended to develop PSS ontology as a support for a PSS design process. The work developed by Aris et al. 2014 is a typical example (see the Figure below). A PSS ontology has been developed aimed at interconnecting explicitely a PSS offering under design to (i) the key product/service solutions to customer oriented problems, then (ii) the key added-value factors addressed. The ontology can be used with a purpose of solution exploration, in a phase of general design. The figure illustrates that the ontology puts into relation a PSS solution (‘Spare parts owned by a supplier’) with components of the solution (circle a), then with value(added factors (circle b). The ontology has been applied to a specific sector (maritime production): its full genericity remains to be demonstrated.

Figure 12 - A PSS ontology to link ‘Added-value factors’ expected, with ‘solution components’ then ‘PSS solution’.

From ontology to meta-modelling

Beyond the definition of concepts through ontological formalisation, the work of (Boucher et al., 2015) intend to go one step forward by proposing to organise these constructs within a generic PSS dedicated meta-model. This work considers the necessity to maintain open this process of building a generic and reusable meta-model: the first version of this meta-model presented in (Boucher & Medini, 2015) is not considered at all as exhaustive and definitive. Built on academic advances, associated with 3 industrial case studies, this first version is a proposal for an iterative meta-modelling procedure further explained in section 12.5. This first and limited version answers to simple requirements for engineering of PSS offer: modelling then evaluating alternative scenarios for a given PSS offers, each scenario being associated to a specific value creation network and economic model.

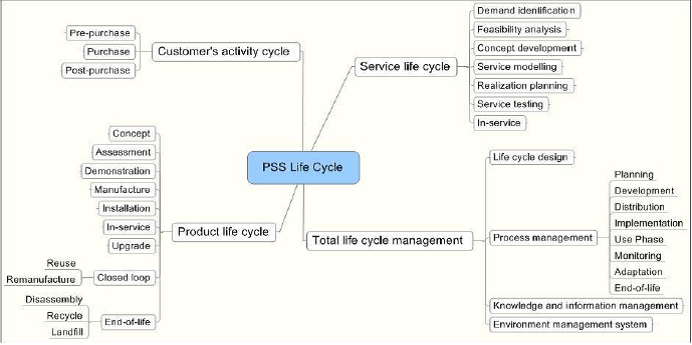

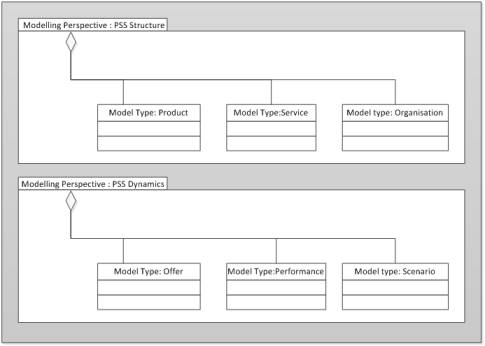

As a result of an iterative meta-modelling approach, the generic meta-model proposed is comprised of six main model types, structured in two complementary perspectives (see the figure below).

Figure 13 - Overall structure of the meta-model

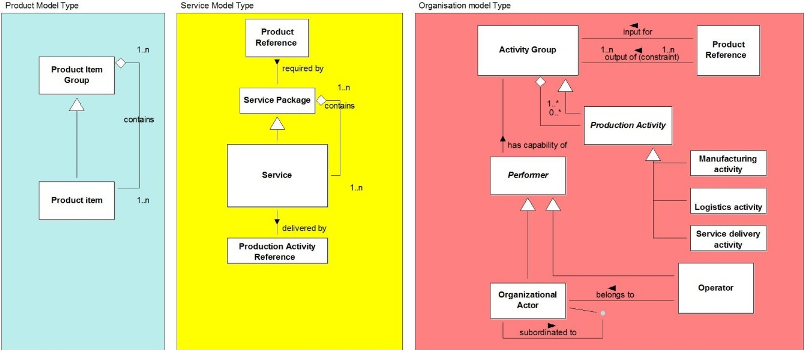

The first perspective (PSS structure) reflects the structural dimension of the PSS, required to formalise the architecture of the PSS offer together with its value creation network. It is constituted by 3 model types:

- The ‘Product Model’, with the objective to represent the overall structure of the material part of the PSS

- The ‘Service Model’, with the objective to represent the intangible components of the PSS offer.

- The ‘Organisation Model’, with the objective to describe the PSS value creation activities and actors.

Figure 14 - PSS Structure-oriented model types

The second perspective (PSS dynamics) correspond to the behavioral dimension of the PSS, including the market behaviors linked to the offer as well as performances factors associated to the organisational capabilities. It is constituted by 3 additional model types:

- The ‘Offer Model’, which specifies the market demand in association with the way combinations of products and services are offered on the market;

- The ‘Performance Models, which states potential indicators which could be used for assessment;

- The ‘Scenario Model’ describing potential configuration of the PSS value-creation chain (called scenarios) for which the performances could be quantitatively analyzed then compared.

Figure 15 - Dynamics model types

Life-Cycle interlacing

Life cycle

Several definitions exist in the literature to describe the life or life history of an entity of interest like a system, a tangible product or a service.

Most of the time, the “life cycle” wording is used to describe the evolution of the entity of interest along its life. Cycle refers to the fact that the evolution may follow several iterations. See ISO/IEC/IEEE 15288:2015 for definition.

Two different descriptions of life cycle coexist in engineering and project management:

- Phase description: the life cycle is seen as a sequence of time periods. This representation is mainly considered in technical management since phases are associated to milestones corresponding to exchange of deliverables between stakeholders and parties.

- Stage description: the stage is the period within the life cycle of an entity that relates to the state of its description, its development or its usage.

Per ISO/IEC TR 24748-1 (IEEE Std 24748-1-2011) or INCOSE Systems Engineering Handbook, the typical life cycle stages of an entity include concept, development, production, utilization, support, and retirement.

Dependency

When considering PSS, several cases of Dependency can be considered between systems, tangible products and services. The main cases are:

- Programmatic or temporal Dependency: the entity of interest can only be considered if several other entities are also kept in the scope.

E.g. temporal dependency is concept is quite close to the project management scheduling concept of “deadline scheduling”

- Structural Dependency: the entity of interest includes several others in its structure.

Note: this inclusion does not mean that the entities are of the same nature (tangible or intangible).

- Functional Dependency: the entity of interest cannot behave without the existence of several others.

Note: Sustainability of the other entities can be either functional or structural:

- Functional sustainability is effective when the entities are involved in collaboration or cooperation, and when the expected outcomes cannot be provided by only one or a subset of the entities.

- Structural sustainability is effective when the functions of entity of interest uses static properties, consumes or produces the other entities.

Note: Dependency has to be considered at any phase or stage of the life cycle of an entity, for the ways it is sustained, its contribution to sustainment and its collaboration.

PSS interlacing Life Cycles

Note: This section will be written later.

Typical examples of life cycle interlacing due to Dependency

Table 2 - examples of life cycle interlacing due to Dependency

| Examples | Dependency |

|---|---|

| System as a service |

The Dependency is between the utilisation stages of both the system and the service. The life cycles of the two entities are not necessary synchronised before and after the utilisation stages. |

| Orchestration or choreography of services |

The Dependency is between the utilisation stages of the involved service. The life cycles of these entities are not necessary synchronised before and after the utilisation stages. |

| Service as interaction paradigm between two entities (products or systems) | Synchronisation of stages of the service and the interacting entities has to be studied stage by stage. |

| Service to sustain a system stage. E.g. system development |

The service utilisation stage is synchronised with the system development stage. However, the service definition (development and production stage) could be needed during the system concept stage. |

| When service offer is dissociated from service provision |

Utilisation phase of the service provision implies an utilisation phase of the service offer. However service offer must be defined (development and production stage) in order to go in concept and development of the service provision. |

Note: A possible extension is to add stakeholders involved and impacted by the Life cycles. E.g. providers, customers, builders, integrators, etc.

Note: Value chain analysis could be added WRT life cycles.

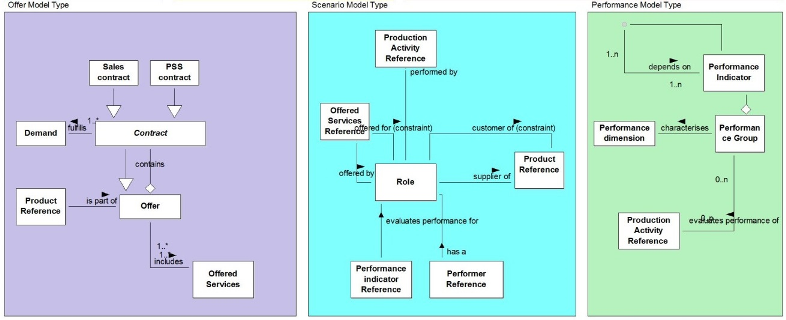

Service delivery versus PSS delivery

We consider that:

- A service as an action performed by a provider to the benefit of a consumer, interaction between both. The provider uses means and has a capability enabling one or more actions. These actions lead to a result or an effect aiming to satisfy consumer requirements against its own actions performed using its own means and capability.

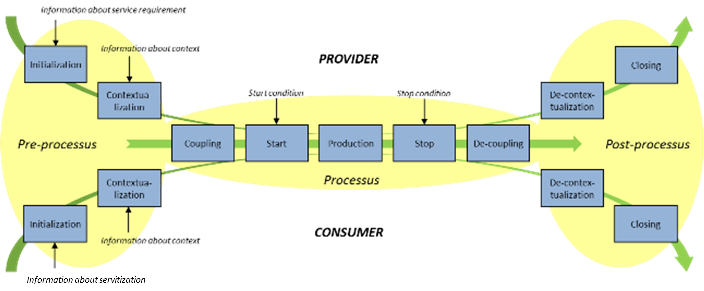

Figure 16 - Service interaction modelling

- A provider is identified with regard to his function and is noted F. A consumer is characterized by his need and is noted B (figure bellow, left part). As a provider can be consumer of one or more services and conversely, we assume that it can be a hybrid object (figure bellow, right part).

- Service delivery relations become then more complex i.e. each relation is defined for a given service. A hybrid object is then part of a service delivery series, linked to another upstream object as consumer and a downstream object as provider.

Figure 17 - Basic principle and hybrid object generic representation

A service delivery process is a process enabling the delivery of a service. It requires a coupling between a provider and consumer and sometimes necessitates means. The service is returned as long as the coupling exists. When it stops, the service ends and each stakeholder find back its freedom. When the coupling starts, requirements have to be elicited by the consumer.

The abovementioned description supposes that the service delivery process can only be led during the coupling. Obviously, the interaction between the service provider/consumer is the main part of the service delivery process. However, in more complex cases both actors can require to be prepared in an upstream phase (some sort of pre-process) and to get free in a downstream phase (some sort of post-process). The corresponding phases are the following ones:

Initialization: this phase does not require the coupling to be established but requires knowing that the service must be returned. Information on the service needs is necessary to activate the phase. Information refers for the consumer to the identification by his requirements and for the provider to the identification of the requests he can satisfy.

Customization and contextualization: in case the service is not standard, a phase of customization based on information coming from consumers is to be envisaged. The contextualization focuses on the adaptation to the context (consumer, surrounding conditions, etc.) of the service to be returned and of the service delivery process.

Closing and de-contextualization phases exist when both actors require a process to close the activity. This process is similar to the one of the initialization phase but occurs after the service delivery. It can lead for the provider in a change regarding its ability to deliver the same service.

Figure 18 - Cartography of the whole service delivery process

Specificities of the economic model

Introduction

The economic model is of course part of the Business Model. However important and specific questions linked to the specificities of PSS have to be addressed, with quantitative insights: this explains this dedicated section. The section is structured in 3 parts:

- General notions of Functional Economy, which conceptually puts forth the specificities of PSS economic models;

- The argumentations on viability issues

- The decision-making challenge of offer engineering.

Change of Business Model through ‘Enterprise servitization’

As underlined by the previous section, the switch from pure manufacturing activity towards product-services systems requires a deep change of business model. The term ‘servitization’ was first used by Vandermerwe and Rada (1988) who defined servitization has a strategy based on « the increased offering of fuller market packages or ‘bundles’ of customer focused combinations of goods, services, support, self-service and knowledge in order to add value to core product offerings ».

From a strategic point of view, servitization has to be differentiated from usual strategies based on cost competition but also from usual strategies based on client loyalty, which only look for volume or integration effects (Zacklad, 2007). Servitization requires a deeper change of mindset, by changing the way to build and deliver value to the client through a new focus on the overall functionalities provided by the product usage. The exchange value process itself requires to be redefined.

The table below provides several complementary definitions and points of view on servitization, making possible to better capture the large view necessary to deal with this issue.

Table 3 - Definitions and points of view on servitization

| Vandermerwe et Rada (1988) | “offering of fuller market packages or ‘bundles’ of customer focused combinations of goods, services, support, self-service and knowledge in order to add value to core product offerings » |

|---|---|

| Allen White, Stoughton, et Feng (1999) | « servicizing: emergence of product-based services, which blurs the frontier between manufacturing activities and more traditional service oriented activities» |

| Lewis et al. (2004) | « Any strategy which intends to change the way a product functionality is delivered on the market » |

| Ren et Gregory (2007) | “A change process where manufacturing companies develop an orientation towards service offers and higher service level delivery, with the aim to improve client satisfaction, obtain competitive advantages and increase firm performance”. |

|

Oliva & Kallenberg 2003 Baines et al, 2007 |

Servitization can be considered as an innovation process requiring adaptation of organizational structures and processes necessary to ensure congruence between their resources needs and capabilities, when implementing a strategic transition from selling product to selling PSS. |

Following Oliva & Kallenberg, then Baines, servitization can thus be considered as a transition strategy of industrial companies towards a new offer and business model based on relational value-creation model, which transforms the internal capabilities and organization of the firm, requiring to consider its distinctive capacities and resources, its strategical visions, as well as the opportunities offered by the economic environment. This vision emphasizes: innovation, strategical dimension, complexity of the organizational transformation, change of model for value creation.

The decision-maker’s motivations to follow a servitization trajectory are quite diverse, some more pro-active and other more re-active. Additionally the way to manage then implement the transition program can differ deeply among the contexts. This strategy deployment is not always a drastic change; it can be programmed progressively, as underlined below.

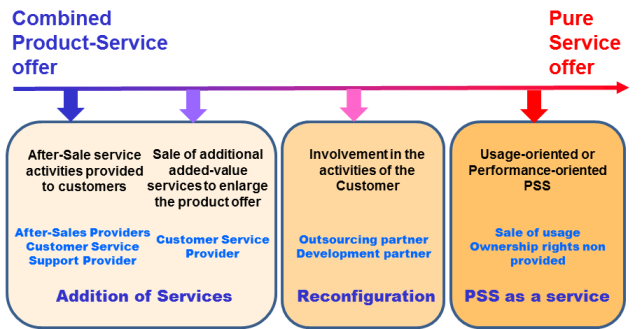

Structure of the servitization process

For industrial companies, a servitization strategy can be deployed progressively. It is also important to emphasize that this process is not always successful, and in several cases related in the literature, it does not come to its end (Neely 2007).

Several authors have described this strategic and organization transition by a progressive transformation (Vandermerwe & Rada 1988) (Martin & Horne 1989) (Mathieu 2001) (Oliva & Kallenberg2003) between two distinct industrial logics: « Good Dominant Logic » versus the « Service Dominant Logic » (Vargo & Lusch 2004) (Vargo & Lusch 2008). This dynamic transformation is gradual and requires a progressing learning process to change the culture on the firm. (Léo & Philippe 1999), underline that ‘the more an industrial firm is advanced in service culture, the more it can find the opportunity to develop quite diversified product based service offers, and then change a customer constraints into revenue increase. The learning process brings industrial managers to change their point of view on the added-value of service activities: service is first a way to increase customer satisfaction, then it turns to be a source of revenue, and possibility becomes a full integrated business model able to supplant product sales.

According to (Beltagui et al. 2007), (Vandermerwe & Rada 1988) an (Van Looy et al. 1998), the servitization process can be described with 3 main phases, which are linked with the place of the service in the overall value creation process on the firm. Several authors describe the progressive change of place for the service provided in the value creation chain (Brax 2005) or conceptualize a repositioning of the value creation point (also called ‘value offering offer’) (Holmström et al. 1999). The more advance development of servitization leads to the value co-creation between client and provider:

- Phase 1: In this initial phase, value remains embedded in the product, and services tend to be still considered as cost centers (typically maintenance);

- Phase 2: the economic model is based on extended-product. It fits economic situation of high competition on a dynamic and international market, with products from all over the planet. In this offer of extended product, service is no more considered as a cost center, but as a differentiation factor. (Neely 2007) underlines the different forms of associations between products and services.

- Phase 3: Finally, the integration of products and services (PSS) is considered as the main source of value. The design process for this integrated offer has to be deeply changed, to consider the full potential of usage-based value creation emerging from the product. This value source relies on product usage, thus on the functionalities of the product. In this value co-creation, the provider is in contractually charge to ensure the functionalities and availability (or performance) of the product.

Deployment of servitization process

In coherence with the general process introduced just above, the ANR ServINNOV project tends to demonstrate the progressivity of servitization deployment for SMEs (Prim-Allaz & Ambroise, 2014). The manufacturing transition through servitization is confronted to in-depth changes at the organizational level: deep change of the offer design process, of organization principles, of internal collective competencies, of external collaboration relationship within the Ecosystem, or to a higher digital integration for manufacturers. But, such complex transition can be managed progressively, and several readiness levels can co-exist in the same firm, for instance in distinct business sectors. The ServINNOV ANR project has developed a quantitative analysis of a large panel of enterprises, which emphasizes the 3 following strategies of transition (see the figure below).

- « Additional-services » (‘services ajoutés’) correspond to a product oriented production, where after-sale and added-value services are added to enrich and complement the product offer.

- The “Reconfiguration” is based on a transformation in the way to manage the value creation chain. The product can be sold to the client, however this can be realized in a context of subcontracting of the production or with subcontracted R&D activities.

- The type of strategy, “Product Service Systems” corresponds to the final full integrated PSS offer, with a contractual engagement between provider and customer to make possible selling a usage, an availability, or a performance.

Figure 19 - Servitization Continuum (Prim-Allaz & Ambroise, 2014)

Therefore, decision-makers should be aware of the good decision criteria to manage the strategical change trajectory of their company (Pellegrin et al., 2013). The results of ServINNOV Project show that managing a servitization process relies on 3 key decision dimensions: (1) the Customer Interface, (2) the Realization System and (3) the Service Culture. These 3 dimensions constitute the key components to build the “Operational Service System”, which gathers all mechanisms, specific for each company, required to deliver services associated to product life-cycles.

The 3 key dimensions to build an “Operational Service System”

– Customer Interface

All mechanisms and working-organization addressing customer relationship management

The level of complexity of Service Interface changes according to the Business Model

The degree of interaction between provider and customer is a key decision variable.

– Service realization system

- All back–office processes contributing to deliver services associated to product-life cycles.

Physical and managerial organization required to deliver services.

The choice of organizational structures and infrastructures are key decision variables

– Service Culture• All processes and organizational mechanisms linked to enterprise culture and Human Ressources management (Enterprise service-oriented culture, working environment, employees empowerment)

Notion of ‘Functional Economy‘

The notion of Functional Economy (Concept more developed in France under the term Economie de fonctionnalités) is developed in the Economical Sciences discipline, directly in relationship with the notion of product-service-systems, which has emerge in Engineering Sciences disciplines. Functional Economy is implemented via PSS. But the contrary is not always verified: a product-service-system does not always require Functional Economy stricto-sensus. Notably, referring to a rigorous definition, Functional Economy includes an intentionality oriented towards sustainable development, which is not always present in industrial PSS.

To understand Functional Economy and some characteristics of its operational deployment in the field, the French national ADEM project report OCEF (Opérationnalisation du concept d’Economie de fonctionnalités) gives an interesting synthesis of key issues and key advances in this domain (EcoSD, 2014). Based on this reports, we highlight below some key definition elements of Functional Economy

According to Walter Stahel, Functional Economy “aims at optimising the use –or the function- of goods and services, by concentrating on the management of existing wealth, under the form of products, knowledge or natural capital. The economical objective is to create a value-in-use the higher possible for the longer time possible, while reducing as much as possible the consumption of material resources and energy. The goal is to gain a higher competitiveness and an increase of company revenues (….)» (Buclet, 2005).

In a more usual approach of product sale, the value is defined as an exchange value: the customer is ready to pay a certain amount in exchange of a good. Vargo & Lusch call it the « Service-dominant logic » versus the « Goods-dominant logic » (Vargo et Lusch, 2004). In this approach, the concept of value moves to re-center on use-value. Thus, Functional Economy focuses on value-in-use and no more value of exchange. The value extracted from a product by a client depends on the benefices he can concretely gain from the product utilization: it the service value, characterized by its performance et its yield over time. In this vision, the customer buys an answer to some global need: the mobility more than the vehicle, the climate comfort more than the electrical heater, the cleaning service more that the washing machine…

Thus, the French Economist C. Du Tertre (2008) defines Functional Economy as « Dynamics of co-production by producers together with consumers, of overall solutions integrating products and services in order to answer needs of people (B2B) or enterprises (B2B), taking into account new environmental and societal requirements”. As such, this economic model is characterized by the following features :

- Economic model with ‘no possession transaction’, but with a sale of service making possible saling the use of goods; thus, economic model based on use-value and no more on transaction-value of the goods.

- Mutualisation of the use of goods, by putting forth service offers which tend to answer ’collective functional needs’: territorialisation of needs.

- Transformation de ‘focus’ of the production processes: new ‘object of production’ based on the integration of product and services over the whole life cycle (Design, Production, End of Life, and Evolution of the offer…).

- Dynamics of co-production (customer/user contribution, collaborative production networks, multiple stakeholders), generating new forms of value creation process & value creation factors.

- An intentionality which should be oriented on environmental and societal requirements

Consequently, the provider should ensure to provide the service on all the life span required, with a low cost, but with the ambition to generate a sufficient revenue and profit. The provider remains in possession of the product and in charge of its maintenance and end-of-life treatment; the exchanges and relationship with the customers are based on repetitive service sales. At the design time, the consequence is the necessity not only to re-design the product for a good adaptability to customer usage variety and for higher lifespan duration, but also design a panel of additional services, as sources of new revenues. With these 2 complementary re-design orientations, Functional Economy can offer a breakthrough making possible to go beyond planned-obsolescence economic models and also can become an innovation driver for a higher economic development.

The notion of ‘value creation’ is transformed, from a rather linear perspective linked to ‘supply chain’, to a more circular and dynamic perspective also linked to intangible assets. Finally, the provider put on the market a ‘value offer’: however this value remains only a ‘potential’ until the customer really experiment it: just at this moment, and with the contribution of the customer, the value is really produced. Thus, in Marketing theory, when addressing value-in-use context, the client is considered himself the creator of the value; he creates it in its own sphere, not only at the time the service is delivered to him, but before, during and after his ‘service experience’ (Gronross, 2011b). The value is no more intergrated within a tangible good, but dynamically and collaboratively created during utilization (Vargo et Lusch, 2004).

Viability of the Economic

The scientific literature on financial consequences of servitisation remains rather weakly developed. However the importance of this issue for PSS deployment is clearly highlighted. The financial dimension is considered as a major incitation factor, which motivates the strategic change of Business Model through servitization (Oliva and Kallenberg, 2003). More precisely, the basic assumptions state that servitization strategies should help industrial companies to stabilize their incomes and improve their profits: "The main financial drivers often mentioned in the literature are higher profit margin and stability of income” (Baines and al. 2009, p.557). For Baines et al. (2009a), the validity of this trend is strengthened by several examples reported by the literature: “There are a diverse range of servitization examples in the literature. These tend to emphasize the potential to maintain revenue streams and improve profitability”.

Thus, the main financial advantages underlined in the literature are the following:

Higher and more stable Incomes (and turnover). On the one hand, in several sectors, the revenue generated by service delivery can become really higher than revenues generated by product sales (Wise et Baumgartner, 1999). On the other hand, servitization can balance a reduction of sale increase by a higher stability of income flows (Sawhney et al. 2004).

Higher margins. Due to lower sensibility to the sale-price competition, PSS offers can open opportunities of higher margin rates with regards to product-only offers; additionally, in general service activities generate higher profitability than products.

Necessity of high investments. Developping PSS offer requires, for industrial companies, to develop a set a new capabilities (structures, process, organizational routines,…). Thus, the transition makes it necessary a real investment: the funding and managerial resources have to be taken from the initial business of the company, i.e. from resources previously assigned to product development and manufacturing in the old business model (Oliva and Kallenberg, 2003). Gebauer et al. (2005) identify what they call the ‘service paradox’: the investment of an industrial company in a service-oriented strategy seldom generates higher economic results. Their conclusions are argued by a study on 30 manufacturing firms from the equipment manufacturing sector. However the added-value could be on other dimensions of the performance.

New forms of risk. The contractualization of service activities induces a distribution of responsibilities among several actors of PSS delivery networks. The risks of loss of service-quality propagate both from service components to product systems and from the client to all stakeholders of the value creation chain. Not only it is necessary to develop and implement pertinent risk management tools on the relationship with the final user and client but, additionally, these tools should be implemented at all the levels of the value creation network.

As a consequence, economic advantages of PSS deployment are confronted to high level risks. Thus, most of current research works underline that the positive influence of servitization on the financial performance of industrial companies has still to be further investigated with in-depth analysis. In his study (10 028 enterprises, in 25 countries), Neely (2008) shows that, if servitized companies are generating higher revenues than pure manufacturing companies, they also tend to generate a sensible lower rate of net profit, with regards to the overall turnover. According to Eggert et al. (2011), the research concerning the relationship between overall industrial profitability and service-based revenues, remains today at rather low level of maturity.

As a conclusion, the scientific literature underlines a set of important issues:

- Analysis of the turnover sensibility (concerning its level, but also stability)

- The transformation of the cost structure for industrial companies

- The new economic and industrial risks to be managed, in the consideration of uncertainty in decision-making anticipation

- The sensibility of product margins to PSS orientation, either on the short term (increase of the Working Capital Requirement, as a consequence on new income pace), or on the long run (increase of liabilities, induced by the fact that there is no more transfer of ownership on the product).

Offer Engineering including Revenue model

Key issues

As a consequence of these non-resolved questions concerning the viability of the economic model, a rigorous management and decision-making for offer engineering and revenue anticipation becomes a key point to manage the implementation of PSS. Decision-support-systems (DSS) for offer engineering should address several complementary needs:

- First, there is an overall requirement to provide concrete solutions to help industrial decision-makers balancing PSS economic models. New economic parameters induced by the integration of services have to be considered to make possible an efficient anticipation of economic risks. This economic model design has to take into account the multiple options of customization for the offer (variety management), induced by the PSS concept.

- Additionally, due to multiple decision-makers derived of the complexity of PSS value offers, the added-value turns out to be difficult to perceive and assess, according all the points of view. In fact, each decision-maker has its own rationality, values, assessment framework and the decision criteria can be rather distinct and even conflictual among the various points of view. Offer engineering aims at bringing smart solutions to such a multi-actor decision-making situation.

- Comparative analyses are also necessary, between old and new economic models. The deployment of a PSS offer requires a good perception and comparative assessment of both the short term and long term added-value of the PSS scenario with regards to mode usual business models.

- Among the important decision-makers, the financial fund provider has to be specifically considered. A specific financial help is often necessary to cover the initial innovation investment. Out of the usual sale model and residual value of products on the market, the nature of the financial risk changes. Funding institutions also require access to new risk evaluation approaches in the phase of offer engineering.

- Finally, the customer economic view is also affected. Gains and cost generated by a global offer can affect several different budget lines by the customer, like decrease of investment level but increase of functioning costs. The economic interest of this new economic model should not only be argued, but also precisely demonstrated in order to help managing such changes among the clients.

Thus, the economic viability of the PSS should be evaluated so as all stakeholders would be well informed about the spins-offs and risks of the PSS. This multi-actor perspective in the decision making process has been often poorly addressed in literature and open several challenges for the PSS viability assessment linked to the heterogeneity of variables that should be taken into account concerning actors, processes, performance drivers, etc….A scenarisation, or even virtualisation, of the designed offer has been proposed as an appropriate tool for tackling this issue, due to the ability of scenarios to represent in a structured and readable way the multiple variables and to provide a common understanding of the future situation. A scenario can be defined as a "description of a possible future that reflects different perspectives on the past, the present and the future". As such, scenarios allow the recognition of potential threats prior to implementation of the PSS solution. To fulfil the customer requests, scenarios associate a specific PSS-configuration (particular combination of product and services), together with the value chain actors the different performers of activities. Offer scenarios allows for putting together all pieces of puzzle: actors, products and services, thus enabling the evaluation. The identification of the alternative scenarios becomes a key element that shapes the organisation structure of the PSS and defines the responsibilities of the actors. Based on this scenarisation approach, quantitative decision-making solutions can be developed, to provide the various stakeholders mentioned above, with customised indicator systems to help their local decisions.

Example of decision-making support

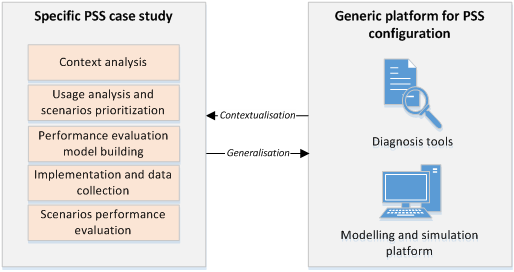

A pertinent example of Decision-Support-System dedicated to balancing PSS economic models is developed in (Medini & Boucher, 2015). A short introduction is proposed below, and for further information on the model, and application to an industrial case study, the reader can refer to the article.

The objective of this methodological framework is to support the rapid development of Decision Support Systems, dedicated to PSS value-chain configuration. The decisional context addressed by the framework involves multiple decision centres representing the actors of the PSS value network. Additionally, it suggests that each of these actors have specific capabilities that may be more or less relevant to the PSS offer. We consider the cases of PSS where the value network is configured around a focal company, which puts the PSS offer on the market and supervises the creation of the full value network. As a hypothesis, the approach considers that each case study is contextualised and, thus, that no fully generic DSS, adaptable to any PSS case study, would be pertinent. In this perspective, the aim of the framework is to take into account special features of each industrial context so as facilitating and fostering the specification, development and implementation of contextualised DSS by managing a generic decision-aid platform together with a contextualization process and mechanism.

The framework is based on a generic platform consisting of a set of diagnosis tools and most importantly the modelling and simulation facilities. Such a platform is supported by a methodological procedure which rigorously structures the way to analyse and apprehend any case-study, then contextualise a decision-support system and, finally provide recommendations on the PSS value network configurations, for the case study considered. Contextualization refers to i) the application of the diagnosis tools to a given case study, and ii) the tailoring process of the simulation model in this case study. Generalization represents the possible requirements that may be extracted from the case study regarding the generic applicability of the diagnosis tools and simulation model. These requirements contribute to continuous improvement of the generic platform.

Figure 20 - Methodological framework for the development of PSS-oriented Decision-Support Systems

The following steps are the backbone of the methodological guidance: context analysis, usage analysis and scenario prioritization, performance evaluation model building and scenario performance evaluation (Medini et al., 2014).

Context analysis combines the firm's mission, objectives and functional areas relating to these objectives. It consists in understanding the company's industrial context and competition factors. This relies on semi-structured interviews with the key PSS actors. The interviews are structured in a way that allows for the SWOT (Strengths, Weaknesses Opportunities, Threats) and PESTEL (Politic, Economic, Social, Technological, Legal) matrix diagram to be filled in for the focal company. As such, this step provides insights into the PSS development opportunities and the main strategic capabilities of the actors involved with regard to the PSS.

Usage analysis and scenario prioritization aims at defining different PSS variants based on the possible distinct uses of the PSS and identifying the value-creation potential for the actors involved (provider, customer and other stakeholders). This step relies primarily on semi-structured interviews, brainstorming, and questionnaires to capture the expectations of both the customer and the actors involved in the PSS delivery. Afterwards, several scenarios are defined in keeping with the expected uses of the PSS. Each scenario consists in a configuration of the PSS offer associated to a configuration of the PSS delivery network, specified by a combination of actors and roles within the network. Finally these scenarios are filtered in order to narrow the scope of the subsequent quantitative evaluation. The filtering criteria stem from the context analysis and stakeholder experience, and are defined during face-to-face meetings. Scenario prioritization consists in putting priorities on the key scenarios which will be submitted to further analysis.

Performance evaluation model building (i.e. Quantitative modelling) aims at building performance evaluation models in keeping with the firm's objectives behind the PSS implementation. More specifically, this step is aimed at defining the performance indicators for each actor involved and identifying physical and financial flows that need to be modelled in order to enable indicator calculation by the use of simulation.

Implementation and data collection. Implementation refers to building the technical simulation environment. This task relies on well-established understanding of the case study context. Such good understanding ensures the consistency of the simulation model with the case study realm. Implementation is accompanied by data collection which is a challenging task because of the multi-actor perspective adopted by the proposed approach and the heterogeneity of the required product and service-related data.

Evaluate scenario performance is a critical step in supporting the decision-making process as it provides an evaluation of several alternative scenarios (consisting in a configuration of the offer and the associated network), thus helping to put the focus on the most interesting ones according to the performance measures. To this end, a three-stage process is deployed and consists in:

Build an experimentation plan: this stage relates to the a priori identification of potential performance scenario drivers based on PSS actor experiences.

Evaluating scenario performance: this stage uses simulation to compute the performance measures upon replicating the real operation of the value network actors.

Identify performance drivers: this stage processes the output of the simulation (performance measures) to identify the most impacting drivers on the performance measures. The tools used at this stage are decision trees forming an efficient and comprehensive tool to identify the impact of different decision levels on the performance. Thresholds can be defined based on this analysis defining the circumstances under which the PSS implementation would be potentially successful.

This step provides insightful information on the viability of alternative scenarios, covering the points of view of various actors and drawing recommendations on which ones to choose: these conclusions remain the final responsibility of decision-makers.

Contribution to a state of the art on modelling, simulation, and engineering of Product-Service Systems

Based on the previous understanding of Product Service Systems and of the industrial transition towards this innovative business model (‘servitization process’), the requirements for advanced ‘System modelling and engineering environments’ can be better understood. These requirements are driven by the decision needs of industrial managers. This situation of Business Models transformation for industrial companies generates strong needs of decision support systems linked to system modelling and engineering (Boucher & Medini, 2016; Cavalieri & Pezzotta 2012). Key issues currently underlined by the academic literature focus on:

strong necessity of supporting tools for the engineering of PSS offers and for the configuration of multi-actor value creation networks;

requirements to manage enterprise transformation programs and assess alternative PSS transition scenarios;

operational management of PSS, with the requirements for advanced PSS life-cycle management solutions.

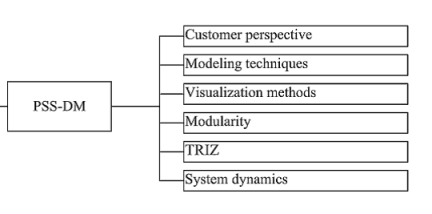

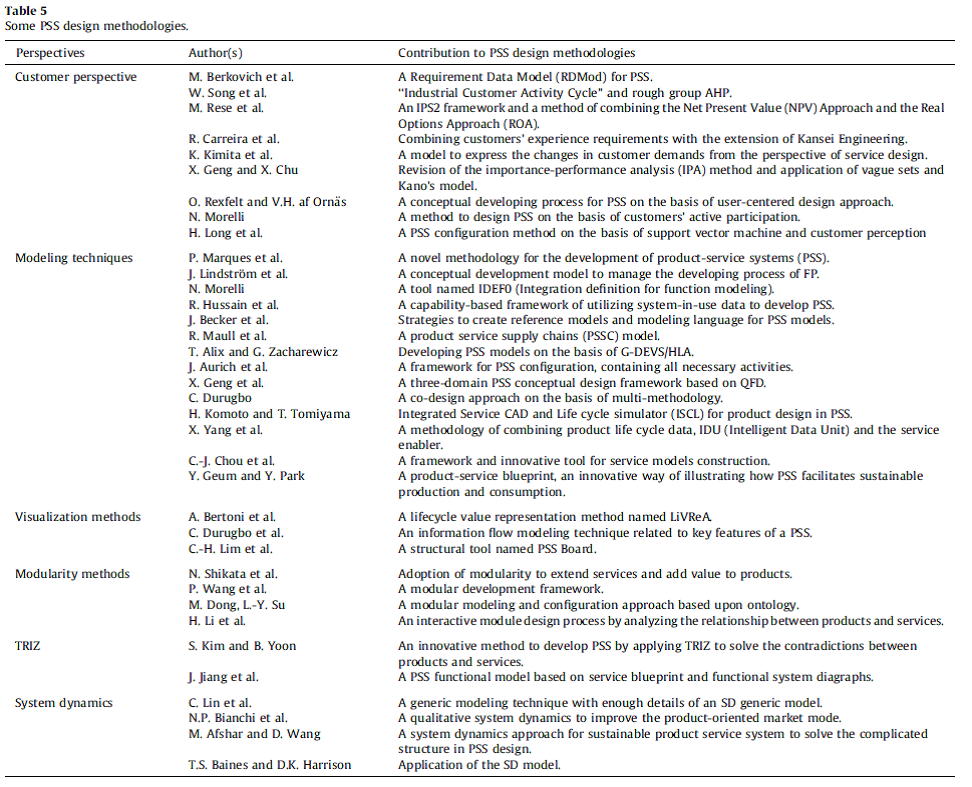

All these needs linked to PSS decision-making are directly linked to System Design and Engineering involving various aspects of virtual enterprise life-cycle: the specification of generic re-usable and customizable PSS-oriented enterprise models has become a key stone of researches in this area. We present below some key elements of the state of the art splitted in 3 sub-sections: PSS Modelling, PSS simulation, then methodologies including both modelling and simulation approaches.

Modelling of Product-Service Systems